- Home

- FAQ’s

FAQ’s

Electrical/Technical FAQ’s

What is a Zig-Zag Grounding Transformer?

A Zig-Zag grounding transformer is a special type of three-phase autotransformer with no secondary or output. It is used to create a neutral point on a three-wire system. Zig-Zag autotransformers are commonly used for several purposes, including ground fault protection, neutral grounding (either solid or through a resistor), and harmonic filtering.

What is an Autotransformer?

An autotransformer is a transformer that has only one winding per phase, with part of the winding shared between both the primary and secondary circuits. Transformers configured in a "Buck-Boost" setup are examples of autotransformers. Autotransformers are designed to adjust the supply voltage where electrical isolation is not necessary and where local electrical codes permit. Unlike isolation transformers, autotransformers can be used in both step-up and step-down applications. They are also commonly used in motor starter circuits to reduce inrush current when starting motors (see Motor Starting Autotransformers for more information).

What is an Isolation Transformer?

All transformers, except autotransformers, are classified as isolation transformers. This is because the primary and secondary windings are electrically isolated from one another (i.e., they are not physically connected). The voltage and current transformation between the primary and secondary windings occurs through the shared magnetic field in the transformer core, a process known as mutual inductance.

What Do I Need to Consider for Transformers Energized at Low Ambient Temperatures?

In dry-type transformers, the surrounding air plays a critical role in their operation. Generally, low ambient temperatures do not negatively impact an energized transformer, as the no-load losses typically generate enough heat to maintain proper conditions, even in environments as cold as -40°C. However, transformers stored at low temperatures present two primary concerns:

- Insulation Brittleness: At low temperatures, the insulation in the coils may become brittle. Expanding conductors when a cold transformer is loaded, or contracting conductors during cold storage, may cause cracks in the insulation, leading to internal faults.

- Condensation Risk: Low temperatures can cause condensation inside the transformer enclosure, as well as on the transformer coils. Energizing a transformer with condensation present on the coils can lead to internal faults and insulation damage.

Transformer Source recommends testing transformers (megger testing), warming them to above 0°C, or following a drying-out procedure if moisture is suspected. Refer to Transformer Source's cold start procedures to ensure safe energization in cold conditions. Energizing a transformer with compromised insulation due to moisture can cause damage and potential safety hazards.

What Are the Storage Requirements for a Dry-Type Transformer?

Transformers that are not installed and energized immediately should be stored in a dry, clean space with a consistent temperature to avoid condensation on the windings. Dry-type transformers with resin-dipped or epoxy-impregnated coils can be stored at ambient temperatures as low as -50°C. However, encapsulated or epoxy-cast coil transformers should not be stored at temperatures below -20°C to prevent cracking.

For best results, store transformers in a heated area with adequate air circulation, away from dust, water, cement, or other contaminants. If outdoor storage is unavoidable, protect the transformer from moisture and debris, leaving the plastic wrapping intact and using silica gel packs to absorb moisture. Check regularly for condensation on critical components like windings, core, and bus cables.

What Are the Standard Service Conditions for a Dry-Type Distribution Transformer?

Unless specifically designed for harsh environments, dry-type distribution transformers typically operate under the following standard service conditions:

- Ambient Temperature: -40°C to +30°C (maximum peak of +40°C)

- Relative Humidity: Less than 70%

- Altitude: Up to 1000 meters (3300 feet) above sea level

To ensure proper operation, avoid installing transformers in environments with excessive moisture, extreme temperatures, or direct sunlight. Maintain recommended clearances and keep all ventilation panels unobstructed.

Can a Transformer Be Connected in Reverse (Backfed)?

Dry-type transformers can generally be connected in reverse (backfed), but there are some precautions to consider:

- Compensated Windings: Control transformers and distribution transformers below 3kVA are designed with overvoltage on the secondary side to compensate for voltage regulation. Backfeeding these transformers may result in lower than expected output voltage.

- Inrush Current: Backfeeding a transformer increases inrush current significantly, which may cause nuisance tripping of breakers. Special considerations may be needed.

- Voltage Taps: Typically, secondary windings lack voltage adjustment taps. Therefore, reverse-feeding transformers must operate within their rated voltage to avoid overexcitation and insulation damage.

- Grounding: When the secondary side of a delta-wye transformer is energized, the neutral is not separately derived and should not be grounded. Always consult local codes before backfeeding transformers.

What Is Temperature Rise?

Temperature rise refers to the increase in the temperature of transformer windings above the ambient temperature when operating at full load. In addition to the average temperature rise of the windings, transformers also experience a "hot spot" temperature, which refers to the highest temperature point in the windings.

For example, a transformer with a 220°C insulation system may be designed with a 150°C average winding temperature rise and a 30°C hot spot allowance. This means that the winding temperature can rise by up to 150°C above the ambient temperature, and the hottest spot in the transformer can rise by an additional 30°C. Combined, this gives a maximum winding temperature of 220°C.

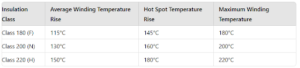

Transformers are designed with different insulation classes, each specifying the maximum permissible temperature rise and corresponding insulation life. Below is a table showing the most common insulation ratings:

Benefits of Lower Temperature Rise:

- Longer Transformer Life: Lower temperature rise means the transformer can operate at a lower overall temperature, extending its life expectancy.

- Handling Higher Ambient Temperatures: Transformers with lower temperature rise ratings can operate safely in higher ambient temperatures without exceeding their insulation limits.

- Increased Overload Capacity: These transformers can handle continuous or short-term overloads without overheating, making them ideal for environments where transformers may be subject to occasional overloading.

Lower temperature rise transformers provide greater flexibility, reliability, and longevity, especially in demanding conditions.

What Is the Life Expectancy of Dry-Type Transformers?

The life expectancy of a dry-type transformer is primarily determined by the insulation system and the operating temperature. According to IEEE Std. C57.96, the deterioration of insulation is directly related to the time and temperature the transformer experiences during operation. Insulation materials degrade faster at higher temperatures, so the transformer’s life expectancy is closely tied to how well it is kept within its design temperature limits.

In most transformers, the highest temperature occurs at a specific point in the windings, known as the hot spot. This area undergoes the most significant wear over time, making it the primary factor in determining the transformer's aging process.

All of Transformer Source's dry-type transformers are designed using UL-listed insulation systems with a maximum hot spot temperature that ensures a design life of at least 30 years under standard operating conditions (continuous rated load, typical ambient temperatures, and no sustained overloads). Transformers designed with reduced temperature rise can extend this design life expectancy to over 50 years, as operating at lower temperatures slows the insulation's aging process.

Factors That Affect Life Expectancy:

- Temperature: As discussed, the most significant factor is the operating temperature of the transformer. Operating continuously at higher temperatures reduces the expected lifespan.

- Humidity and Condensation: Humid environments or condensation can affect the insulation material and lead to premature failure. Proper storage and maintenance help mitigate this risk.

- Short Circuit Events: Sudden surges or short circuits can damage internal components and shorten the transformer’s life.

- Overloading: Continuous overloading beyond the transformer’s rated capacity generates excess heat, which accelerates insulation degradation.

- Environmental Conditions: Extreme environments, such as exposure to dust, moisture, or chemicals, can also lead to earlier-than-expected failure.

By following proper installation and maintenance practices, such as avoiding overloading and ensuring the transformer operates within its designed ambient temperature, you can significantly extend its lifespan. Transformer Source’s high-quality transformers are built for durability, ensuring reliable performance for decades under standard conditions.

Order, Shipping, and Returns FAQ’s

How Do I Return or Cancel an Order?

To initiate a return, please contact us at sales@transformersource.ca. Our team will guide you through the return process, ensuring it is as smooth as possible.

Can I Cancel or Modify My Order?

If your order has not yet shipped, it can be canceled by sending a written request to sales@transformersource.ca. Please review our cancellation policy for any applicable fees. If you forgot to add an item to your order, we recommend placing a new order. We will do our best to consolidate your orders before shipping.

When Will I Receive My Order?

For in-stock items, orders are typically shipped the next business day. If the item is out of stock, please refer to the estimated lead times provided. We pride ourselves on industry-leading on-time delivery. Customers with an account can track the production status of out-of-stock items.

Does My Order Have a Tracking Number?

Yes, all orders shipped within Canada and the U.S. include a tracking number. Once your order has shipped, the tracking information will be available on the order page within your account. You will also receive a confirmation email containing the tracking number.

How Do I Get My Order If I Choose Pickup?

During checkout, you can select the option to pick up your order or arrange your own shipping from our warehouse, located in Concord, ON. Once your order is ready, you will receive detailed instructions for pickup.

Do You Offer Discounts or Special Pricing?

Our prices are updated regularly to remain competitive. We offer special pricing on select items and product categories. Custom quotes from our sales team are valid for 30 days. For more information, please reach out to sales@transformersource.ca.

Discount tiers for bulk orders are as follows:

Orders of 3-4 units: 5% discount at checkout.

Orders of 5 or more units: 10% discount at checkout.

Orders of 10 or more units: please contact us directly for special pricing.

IF YOU HAVE ANY QUESTIONS, LET US KNOW!

Do you have any questions? Contact us and our specialists will answer you.